Description

POLYURETHANE PRIMER

Consolidating resin and against humidity for the treatment of absorbent surfaces or floors.

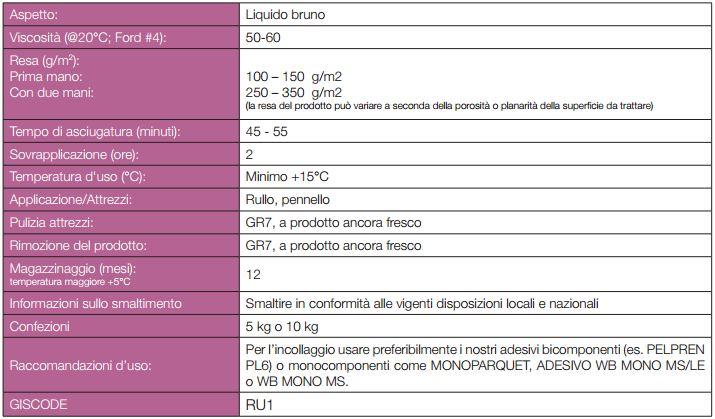

TECHNICAL FEATURES:

- Single component

- 100% polyurethane

- Odorless

- Free from solvents

- Quick drying 45 – 55 minutes

- High barrier against residual humidity (max. 5 – 6 %)

- Consolidating properties

APPLICATION AREA:

- Absorbent floors

- Traditional cement screeds

- Anhydride screeds

- Calcium sulphate based screeds

- Underfloor heating or cooling absorbent substrates

SUBSTRATE PREPARATION

Always check the humidity of the substrate with suitable instruments. The substrate to be treated must be

compact and free of detaching parts and compliant with DIN 18356. Any surface defects,

such as fissures or cracks, they should be treated by mixing fine sand (not marine) with fine PRIMER WB PU

to obtain a homogeneous mortar.

Before applying, make sure there is an adequate vapor barrier.

APPLICATION

Ambient and mix the product before use. Always check the compactness and humidity of the

screed (max 5 – 6 %).

Apply the first coat of PRIMER WB PU with a roller or brush. Leave to dry in a ventilated place at 45 - 55

minutes in suitable environmental conditions +15°C – 25°C and 50 – 70% RH (different conditions can lead to

less than excellent results or a variation in drying times).

If necessary, apply a second coat of PRIMER WB PU within 12 hours and, if applicable

of 1 leveling agent, spread some fine and dry quartz sand (not marine) on the last coat of primer.

Subsequently (after about 2 hours) remove excess sand before gluing which is to be

done within 24 hours.

Always use adequate individual protection systems.

Always consult the technical and safety data sheet of the product.

Estimate shipping

Questions & Answers loading...