Description

SINGLE-COMPONENT SOLVENT-BASED POLYURETHANE RESIN

Consolidating and waterproofing resin for dusty and friable cementitious substrates with residual humidity

elevated.

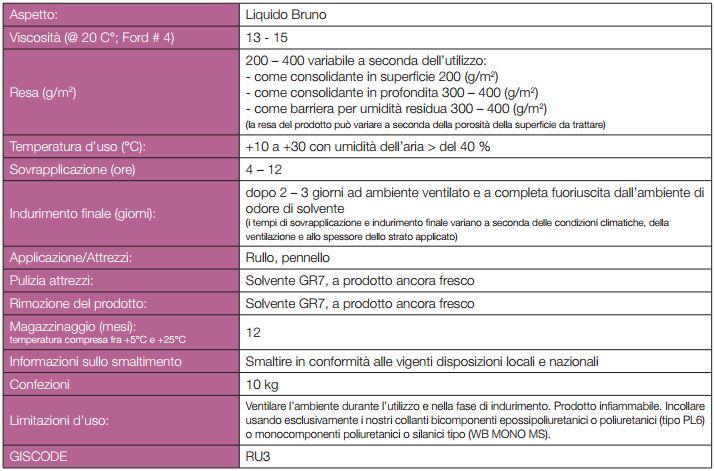

TECHNICAL FEATURES:

- Single component

- High performance (consolidating power)

- High barrier against residual humidity (max 4 – 5 %)

- High penetration

- Increases the mechanical resistance of the surface

APPLICATION AREA:

- Traditional cement screeds

- Anhydride or gypsum screeds

- Preparation of synthetic mortars

- Consolidation of heated screeds (after filling any cracks or fissures that prevent the

direct contact of the primer with the pipes)

DO NOT USE:

- For waterproofing heated screeds (which must have a residual humidity required by law

and suitably seasoned through a thermal cycle)

- On non-absorbent substrates

- In renovations with adjacent inhabited rooms in order to avoid the diffusion of the solvent

- Before laying materials sensitive to solvents (pvc, rubber, linoleum)

- On surfaces subject to continuous rising damp and which are not protected by a vapor barrier

- On screeds containing materials that can dissolve or weaken in contact with the solvent

SUBSTRATE PREPARATION

Always check the humidity of the substrate with suitable instruments. The substrate to be treated must be compact and free of detaching and compliant parts

to DIN 18356. Any surface defects, such as cracks or fissures should be treated by mixing fine sand (not marine) with

PRIMER PA 400 until obtaining a homogeneous mortar to avoid infiltrations or stagnation of product in the cavity with the risk of damaging

any pipes. Substrates with a poorly absorbent layer must be roughened and carefully vacuumed to allow the penetration of the

product. Before applying, make sure there is an adequate vapor barrier.

APPLICATION

Ambient and shake the product thoroughly before use. Apply at room temperature between 10°C and 30°C with air humidity >

by 40% (different conditions can lead to a considerable variation in drying times with less than excellent results). Ventilate the room during

use and in the hardening phase.

As a surface consolidant:

Apply a coat of primer PA 400 in a 2:1 dilution ratio with the special D40 thinner, respecting the yield of approximately 200 (g/m2

).

As a consolidant in depth:

Apply a coat of primer PA 400 in a 1:1 dilution ratio with the special D40 thinner. Subsequently when the primer is dry (about 4 hours), apply

a second coat of primer within 12 hours in a 2:1 dilution ratio respecting the overall coverage of approximately 400 (g/m2

).

As a barrier against residual moisture:

Apply a coat of primer PA 400 in a 1:1 dilution ratio with the special D40 thinner. Subsequently when the primer is dry (about 4 hours), apply

a second coat of primer within 12 hours, undiluted, respecting the overall yield of approximately 400 (g/m2

). If necessary, apply a third coat of

produced after drying the previous coat.

While the product is still fresh, remove any primer residue using a cloth soaked in our SOLVENTE GR7. After hardening

primer PA 400 can only be removed mechanically. To promote greater adhesion of the adhesives, spread a layer of fine, dry sand

(not marine) on the last coat of primer while the product is still fresh. Glue using only our two-component epoxy-polyurethane glues or

polyurethanes (type PL6) or single-component polyurethanes or silanes type (WB MONO MS).

Always use adequate individual protection systems. Before use, always consult the technical and safety data sheet of the product.

Estimate shipping

Questions & Answers loading...