HAI IN MANO PREVENTIVI SULLA TUA MARCA E MODELLO DI PARQUET PREFERITO MA NON TI FIDI?

METTICI ALLA PROVA!

Lavoriamo a stretto contatto con oltre 200 produttori da tutto il mondo, compara il tuo preventivo con il nostro, possiamo offrirti anche la posa certificata in tutta Europa a prezzi molto competitivi.

Da oggi con il nuovo servizio on demand puoi richiedere un preventivo sulla marca ed il modello di parquet che preferisci ed i nostri operatori risponderanno in meno di 24h.

PROVALO SUBITO! Sapremo stupirti!

CHIEDI UN PREVENTIVO ORA!ALL OUR LAST VIDEOS

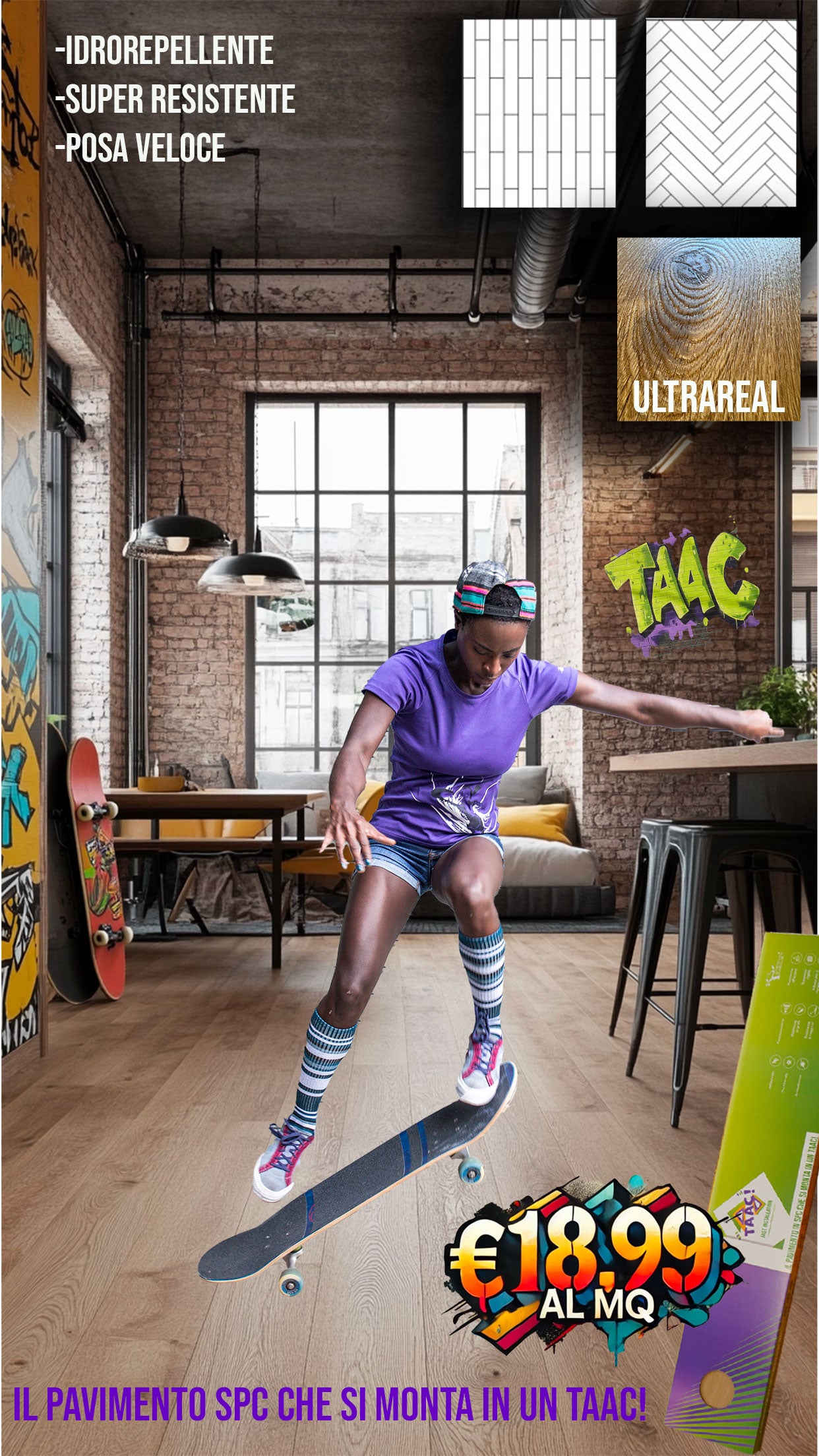

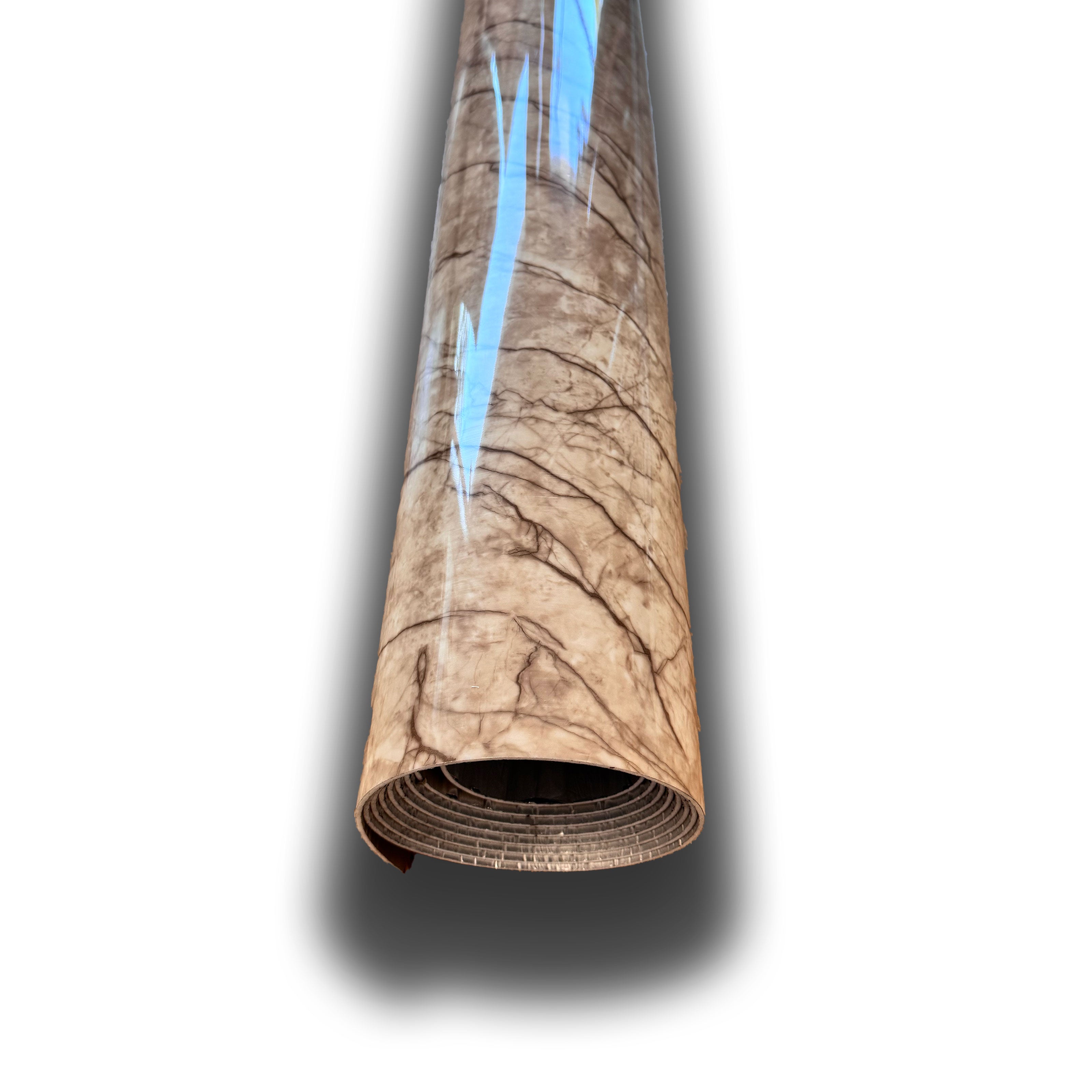

NEW CLICK SPCs

Integrated mat

FIND OUT MORE'

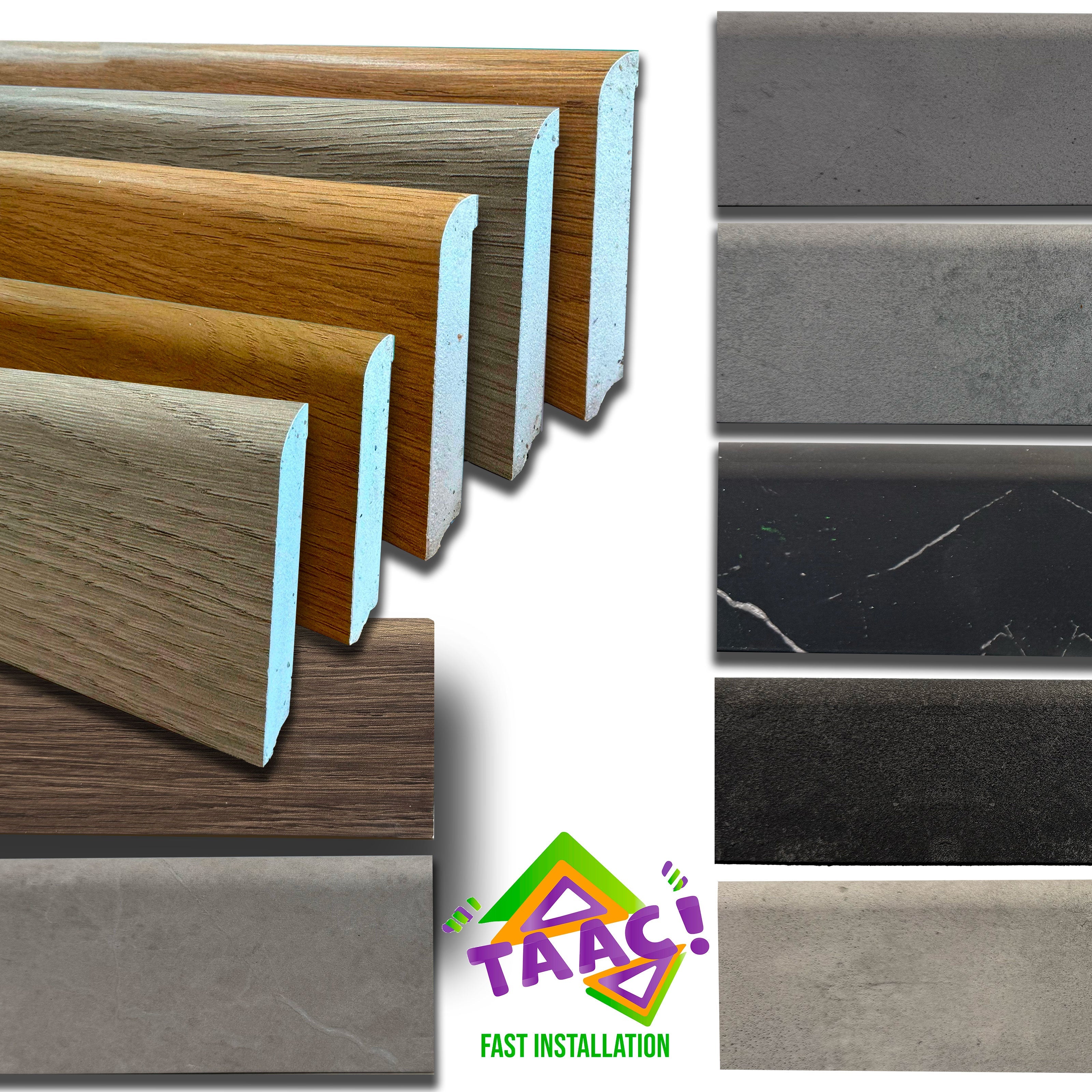

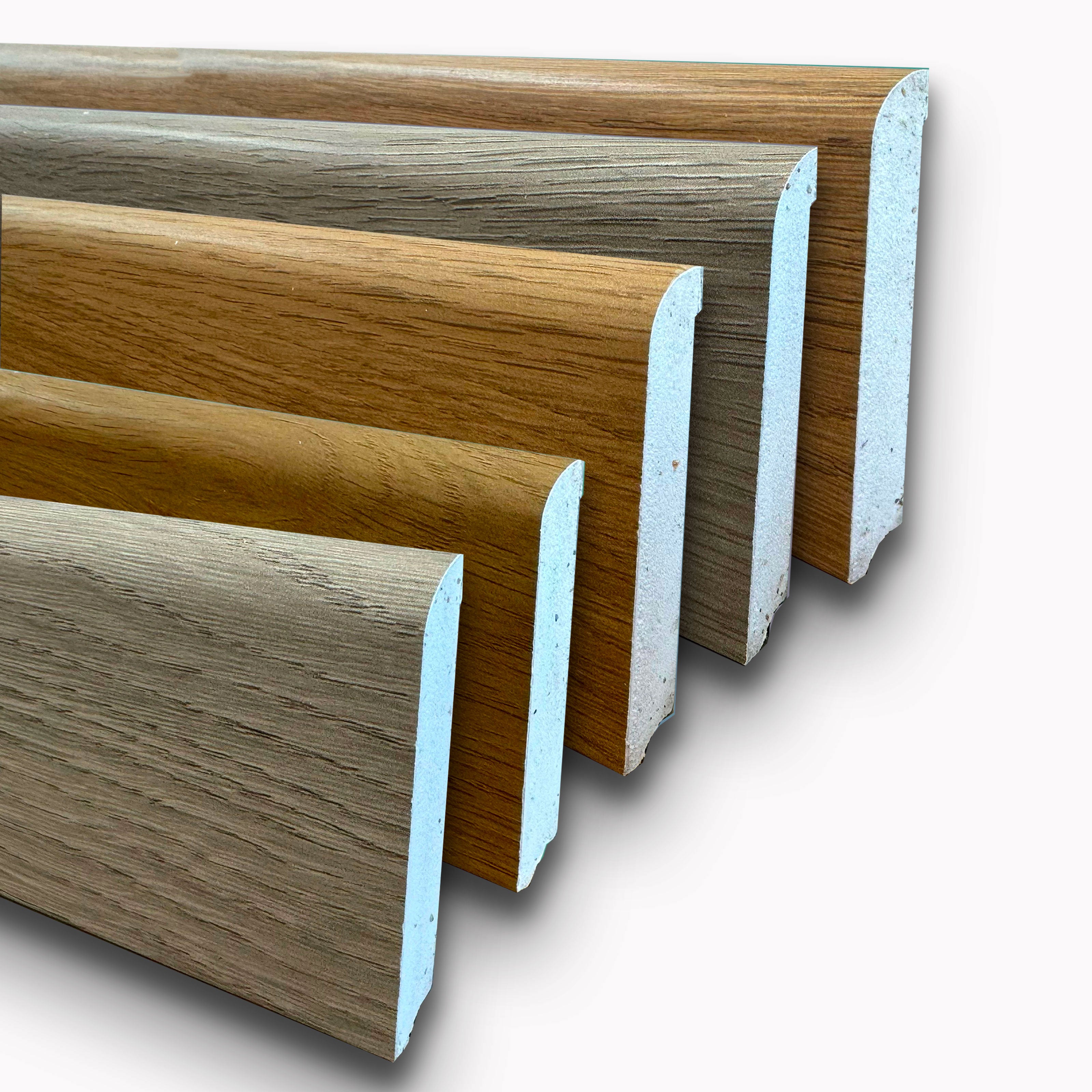

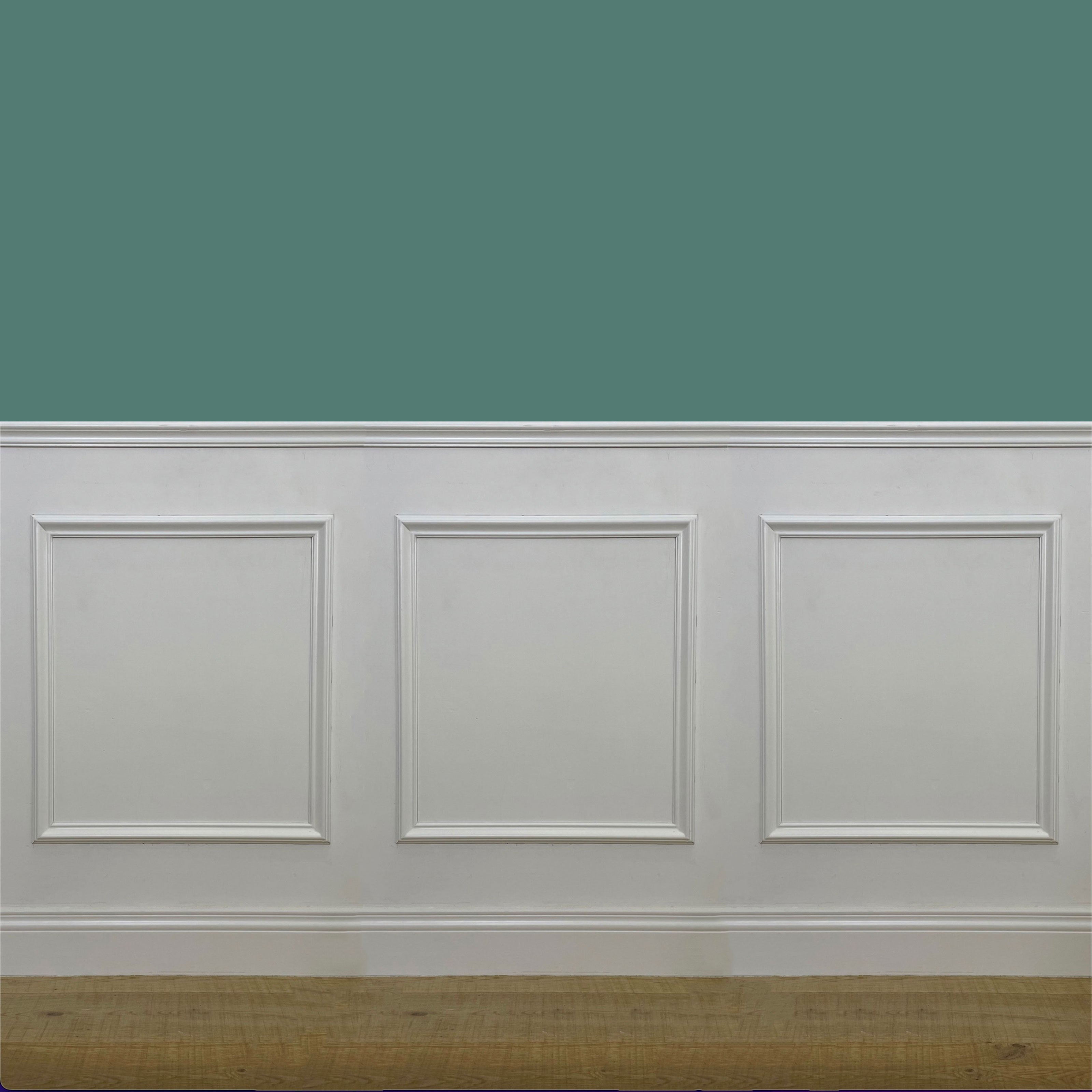

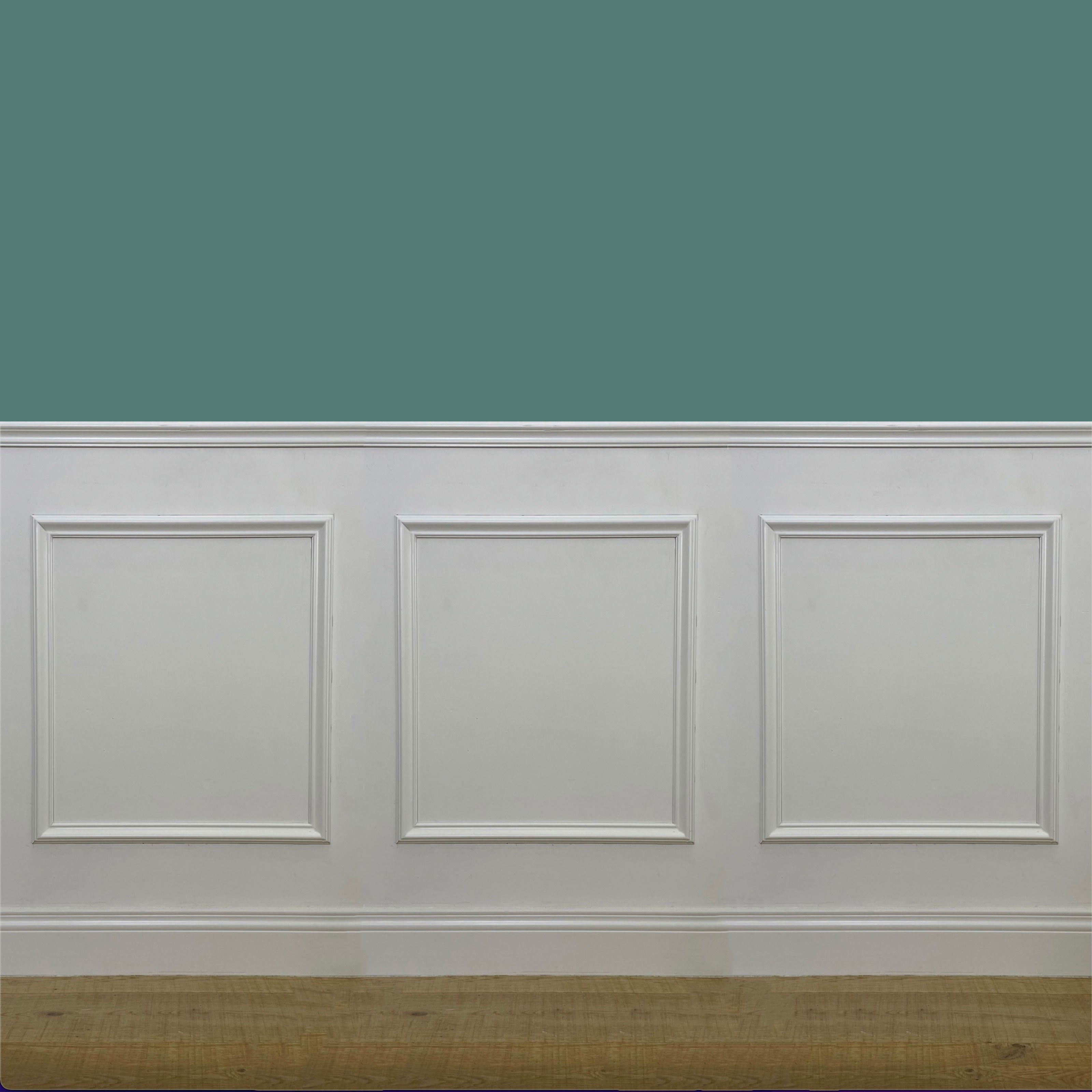

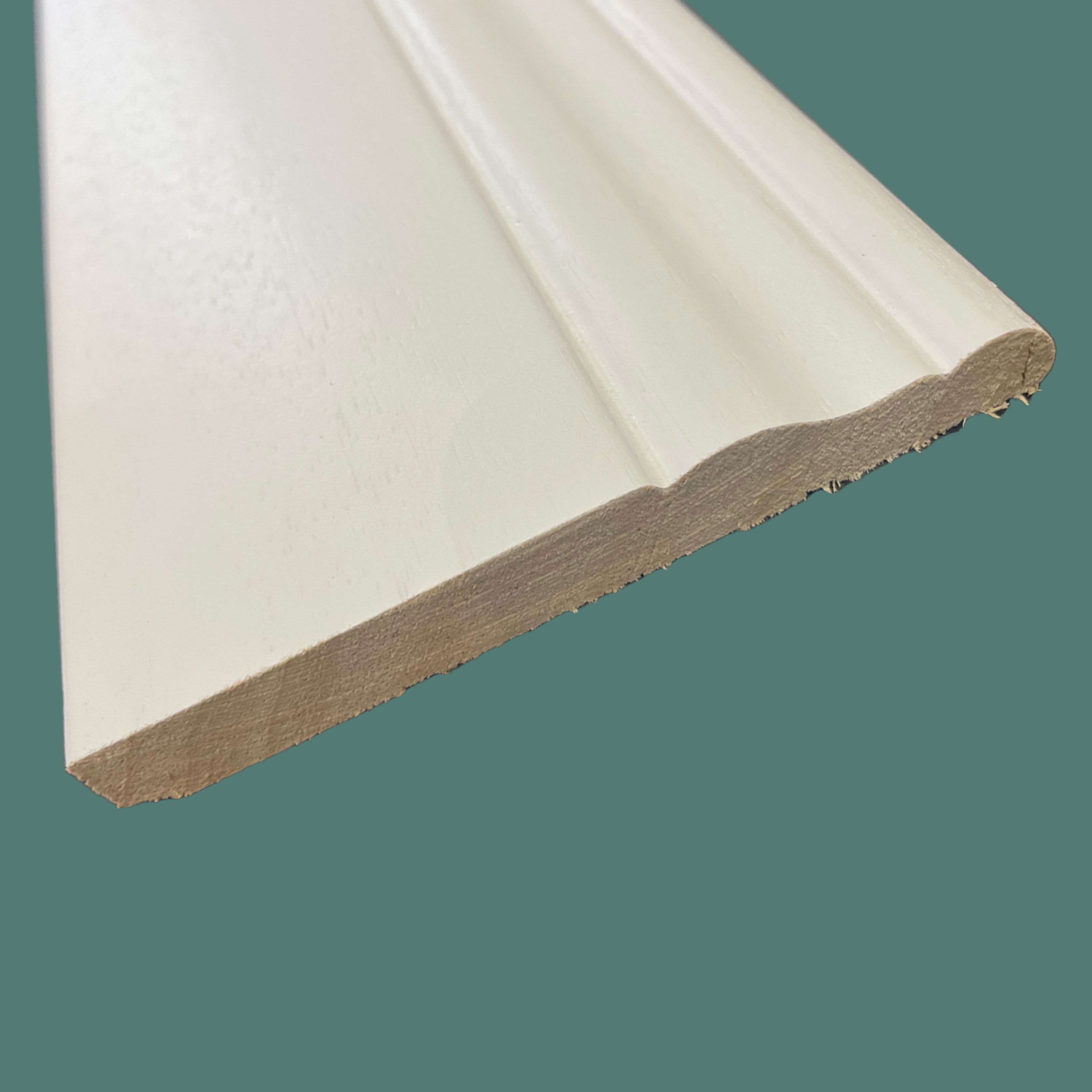

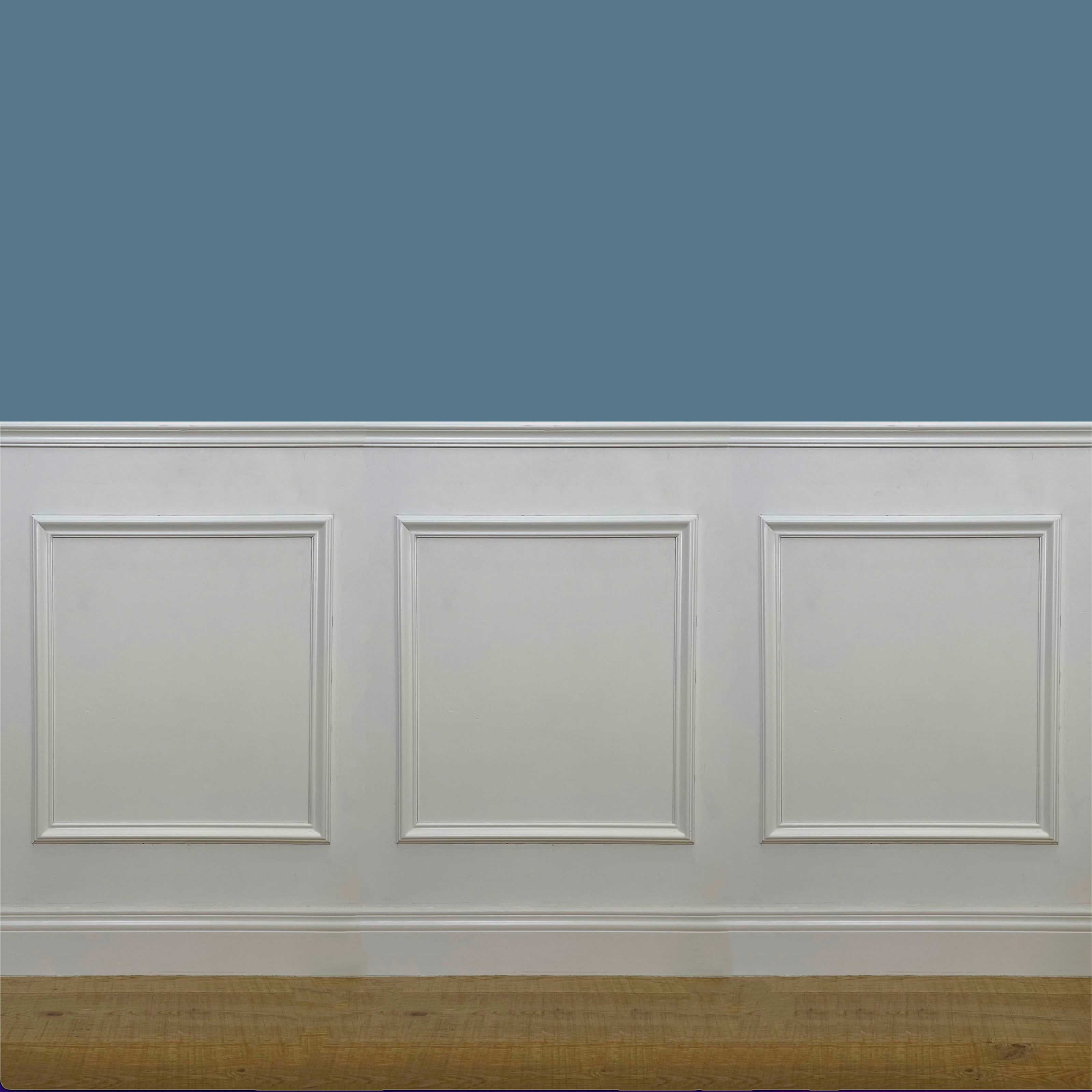

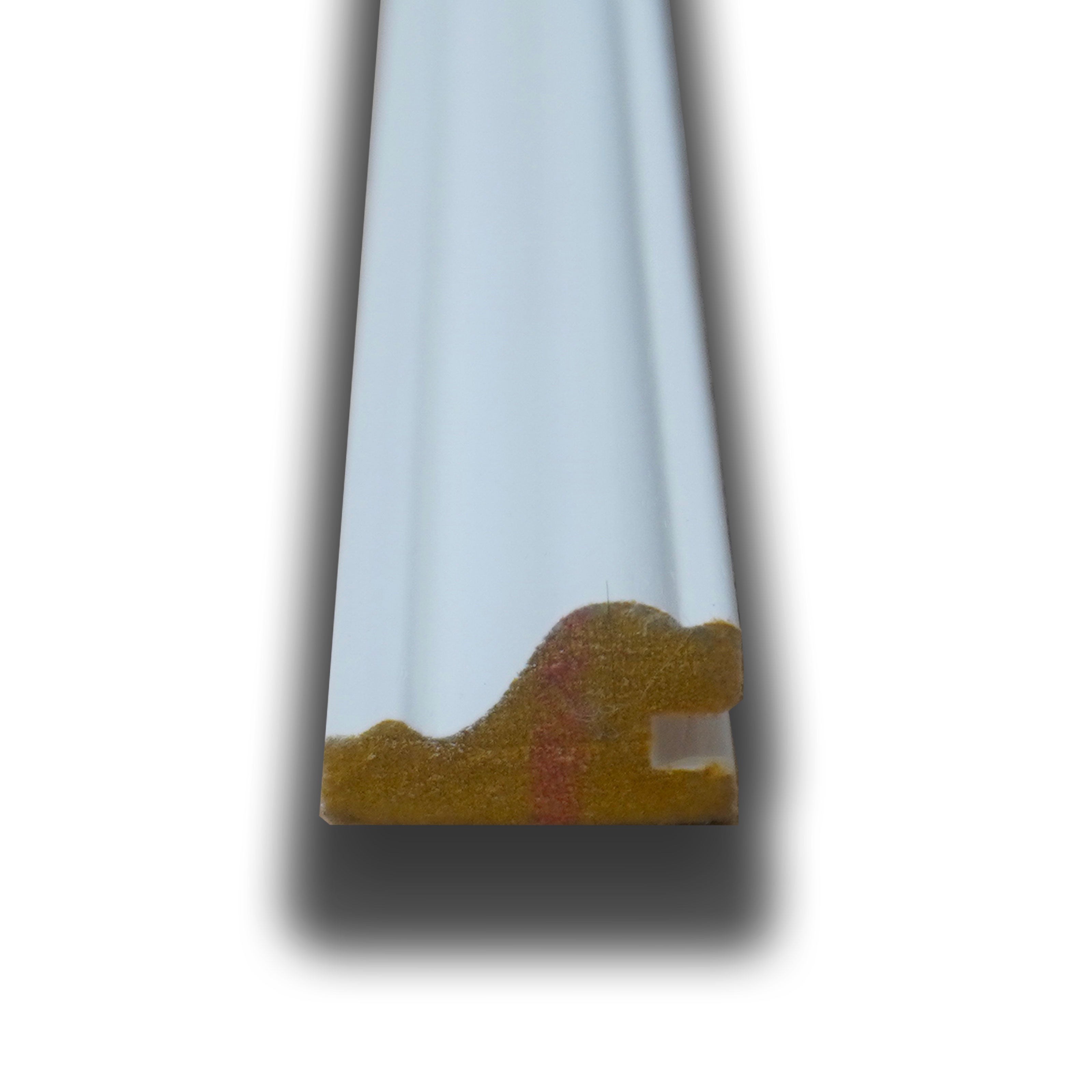

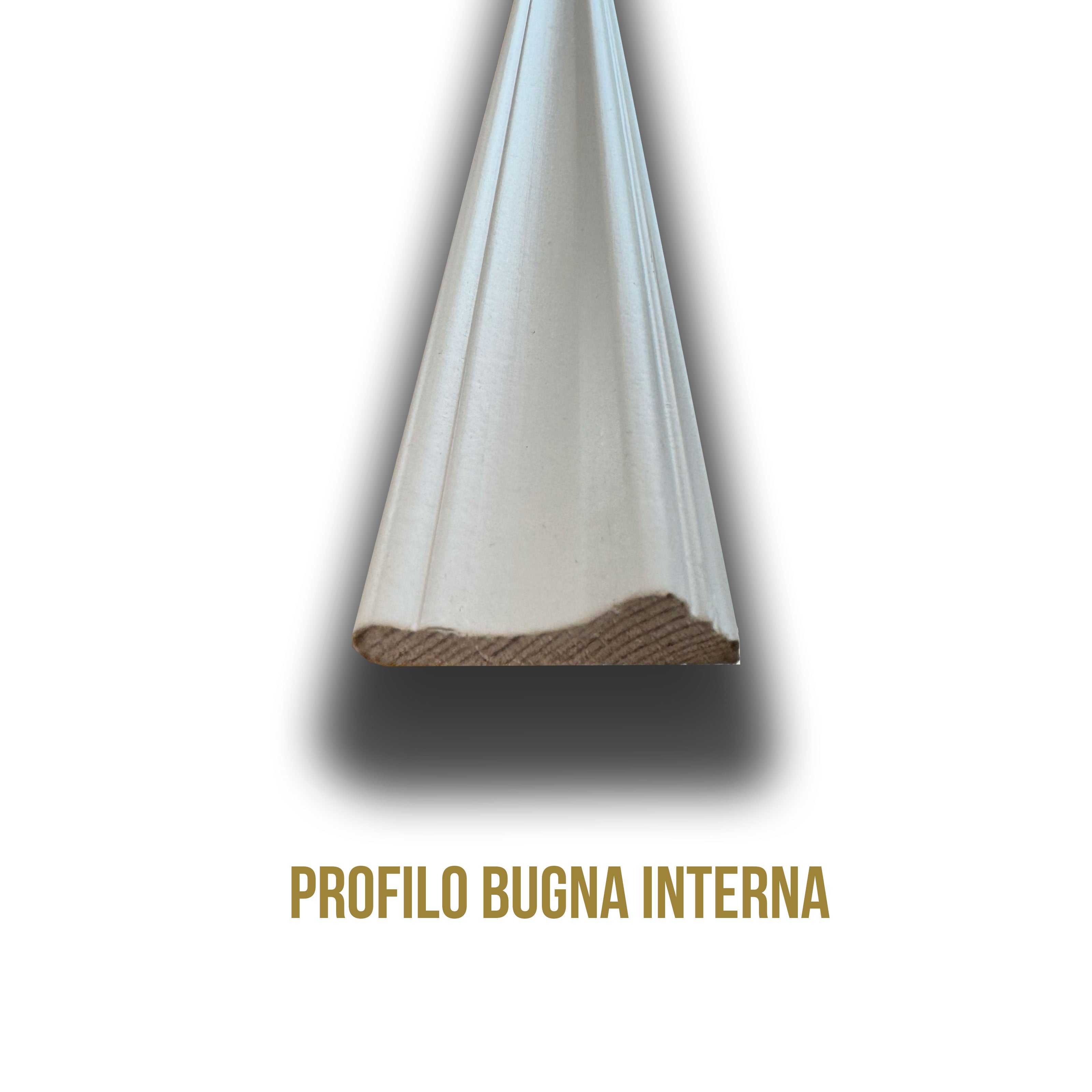

Wall-mounted PVC panels

Ultrarealistic 3D Insulating Effect

OR

Must-have

Cleaning and Maintenance

Free shipping.

Free shipping on many parquet and most products.

Touch with your hand?

Request the sampleFree available for skirting and parquet.

* Transport cost only.

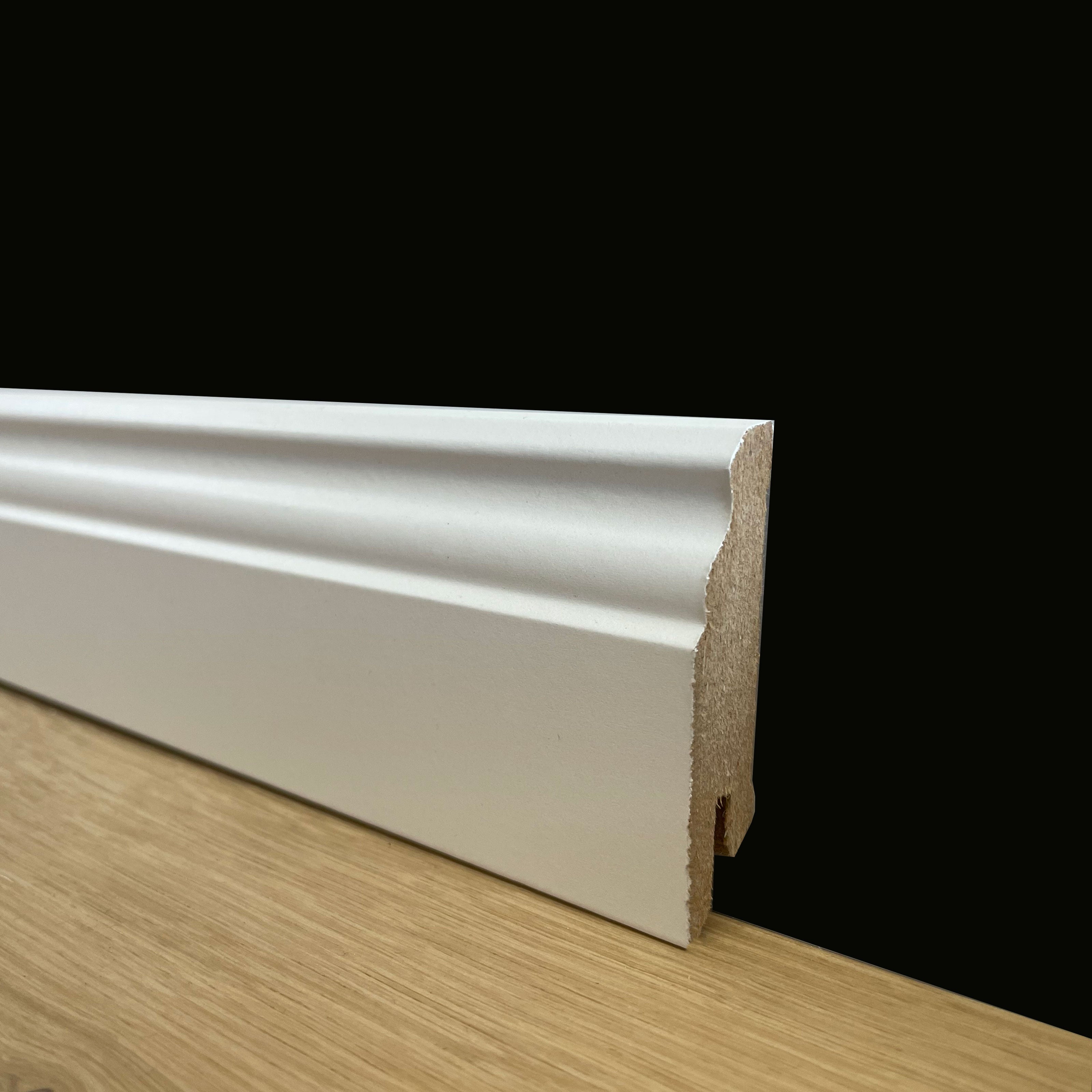

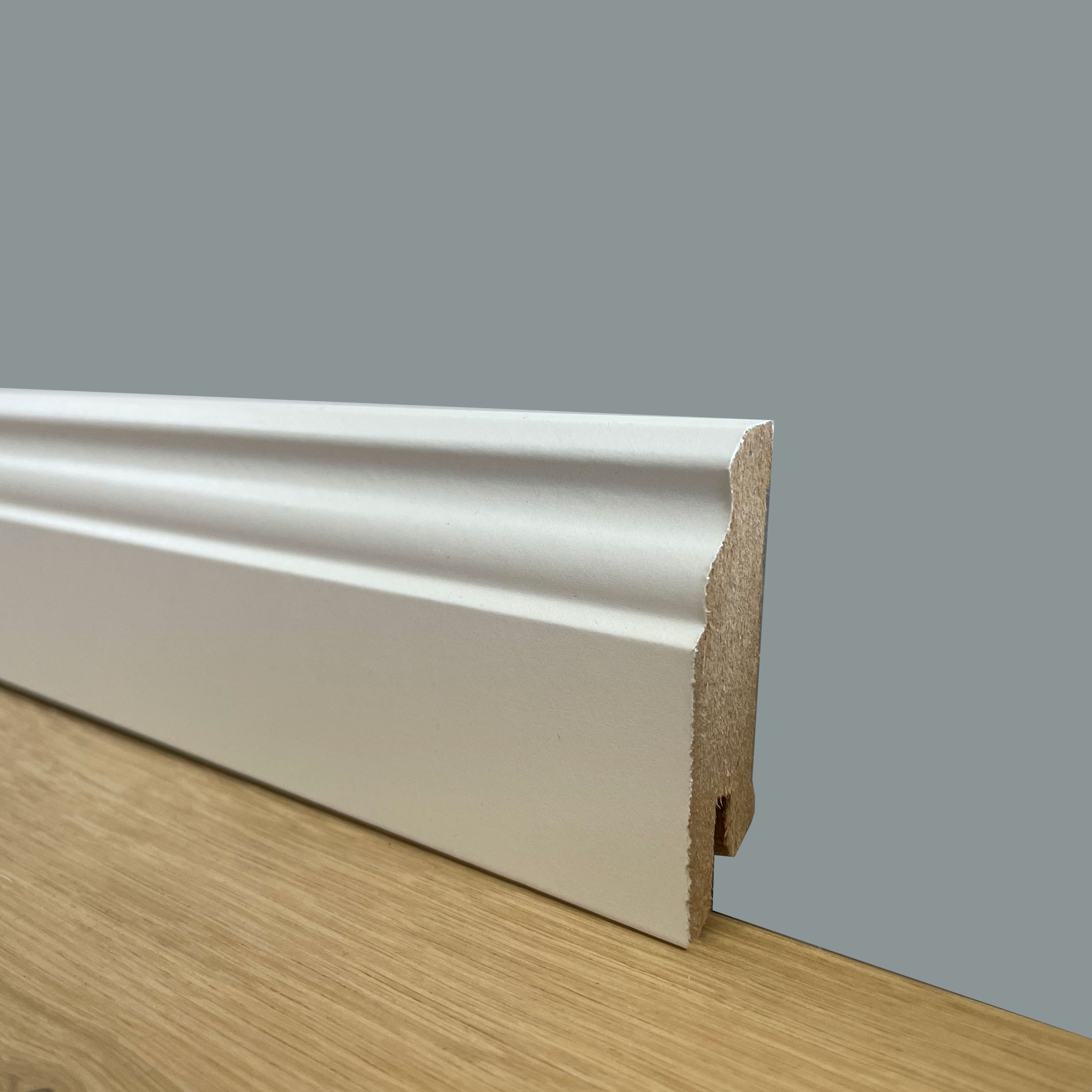

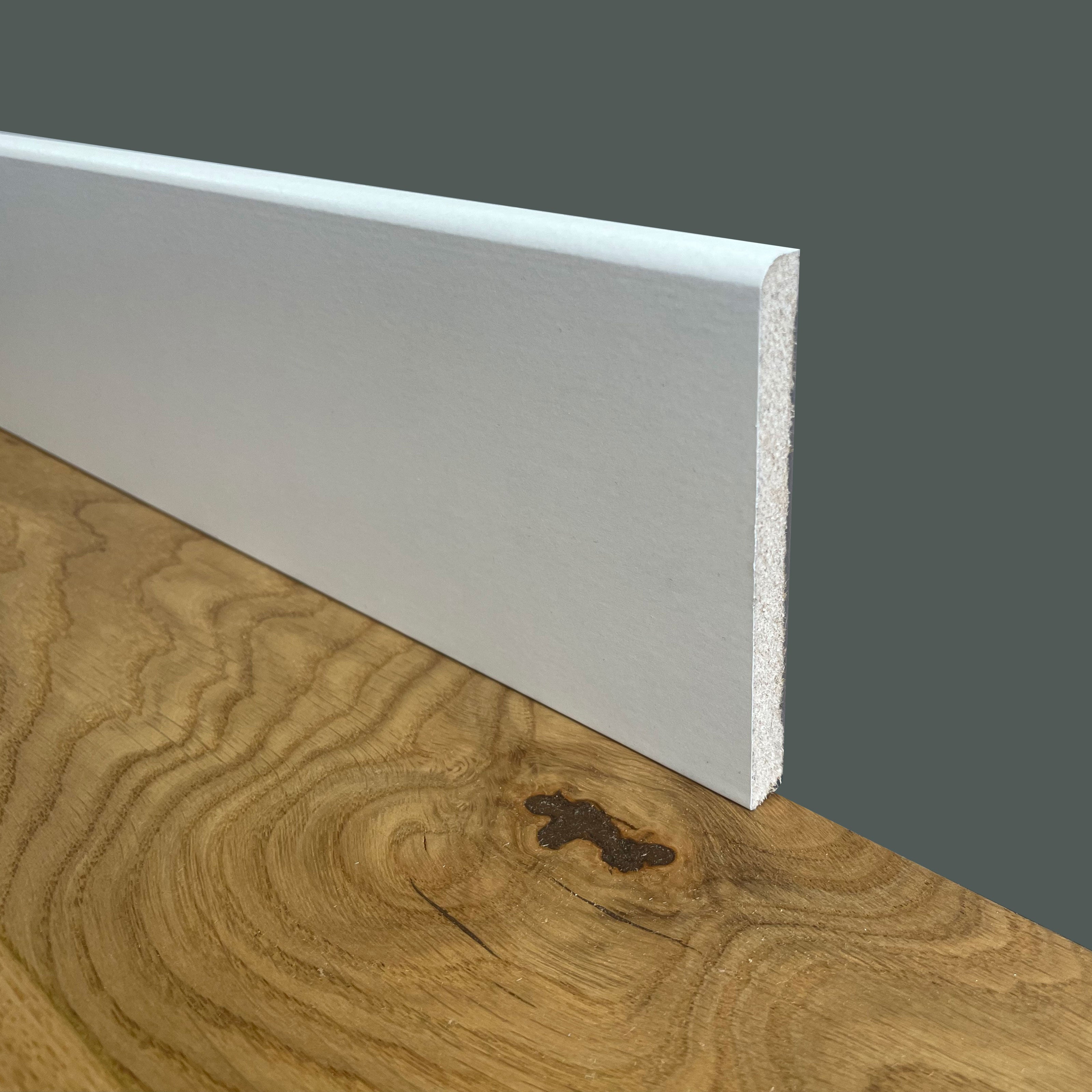

Bestsellers

Most viewed and sold products

Show All

Let customers speak for us

Who is Eternal Parquet

Our success is guaranteed thanks to a careful selection of suppliers. The search for the best product at a great value for money, the advice of our consultants and the tracking of each shipment represent our strengths.

CatalogNews from our Blog

See all items

Pavimenti e Rivestimenti Professionali per Palestre, Ristoranti, Hotel e B&B

Pavimenti e rivestimenti per hotel e B&B: eleganza, resistenza e comfort

Our selling points:

In Via Fontananuova 72 - 83031 Ariano Irpino (AV)

Monday-Saturday: 8.30-13.30

Monday-Saturday: 15.30-20.00

* Sunday by appointment only